The Autonomous Fab is Here

Unlock 95% of your fab's hidden intelligence. Our AI predicts and prevents costly excursions to slash scrap costs, cut cycle time by 30%, and scale your output 1.3x—all without new CAPEX.

Trusted by Top Semiconductor companies

Inside classifAI: How AI is Revolutionizing Defect Classification in Fabs & OSATs.

Read NowYour Fab's AI Control Room: Our Flagship Solutions

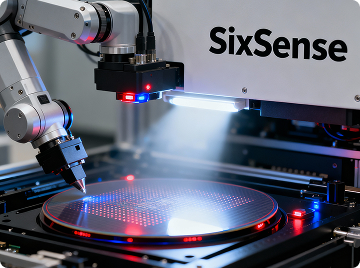

Sixsense is a purpose-built AI platform for fabs and OSATs, automating defect inspection to lot disposition to root cause analysis of defect.

- AI-ADC is our end-to-end solution for automating visual inspection, with tools for training, deployment, and model maintenance.

- Lot Disposition and Root-Cause Analysis brings intelligence to lot disposition by highlighting high-risk wafers based on defect severity and yield impact. It helps prioritize reviews, recover yield, and reduce escapes and scrap.

- Predict AI Go beyond automation—AI predicts when, where, and what to inspect, enabling proactive action that cuts scrap, reduces downtime, and drives self-optimizing fabs.

AI-ADC: Automated Defect Classification at Line

AI-ADC is a real-time vision engine that analyzes every captured image and classifies suspected defects into hundreds of types with over 99% accuracy and zero escapee. It converts defect images into meaningful insights at line speed—slashing review queues, freeing clean-room headcount, and providing a rock-solid foundation for downstream analytics. Fabs can now scale without concerns about hiring, training, or human-driven quality slips.

Lot Disposition and Root-Cause Analysis

Built on AI-ADC's trusted labels, Lot Disposition automatically decides pass, hold, rework, or scrap for each lot—balancing yield impact, recurrence patterns, and defect severity. Always-on AI agents correlate classified defects with tool, recipe, and chamber data across hundreds of steps, instantly flagging parameters drifting out of spec, quantifying yield exposure, and surfacing the quickest fix. What once took weeks now takes minutes—safeguarding future yield with speed and precision.

Predict AI

Move beyond automation and correlation into prediction—where AI intelligently forecasts when, where, and what to inspect by learning defect likelihood across time, layers, and lots. These insights trigger proactive adjustments to inspection sampling and tools before faults occur, dramatically reducing scrap and downtime. As a result, fabs shift from reactive firefighting to self-optimizing production, guided entirely by data-driven agents.

Proven Value, Measurable Impact

Automating 100s of millions of images/year

AI classifies every suspected defect 24/7, giving round-the-clock coverage and reducing footprint in clean rooms.

30% Improvement in Cycle time

Instant pass/fail decisions by AI keep the lots moving; hours get saved at each review step and add savings in up to days for the fab.

1% Improvement in Yield

By catching even the tiniest critical defects early, AI lets engineers correct the process before scrap accumulates—saving thousands of dies that would have been tossed. It also prevents unnecessary over-rejection that comes from cautious manual screening.

12% Reduction in Quality Issues

Consistent, bias-free checks stop bad wafers from moving downstream, slashing reworks, scraps, RMAs and customer complaints from field failures.

90% Reduction in man machine ratio:

AI now does the work of dozens of operators, freeing people for higher-value engineering and improvement tasks.

Loved by Yield Engineers

Sixsense AI: Revolutionizing Defect Classification

"We've worked with Sixsense since the early days, and it's been a game-changer. With their explainable AI tools and intuitive platform, we've cut model launch time from months to just days, while consistently hitting accuracy and automation targets. With Sixsense, a small group manages, trains, and deploys AI models with ease. The models require minimum retraining in production, and we have not seen defect escapees post-launch. We're really excited about the future of AI and we're confident that Sixsense will continue to be a leader in this field."

Yield Engineer

Sixsense AI: Achieving Unparalleled Accuracy

"I evaluated multiple AI solutions — including from top global vendors — but Sixsense stood out. ClassifAI hit 99% accuracy in just hours. The model could learn defect patterns across multiple devices, making it extremely adaptable to our manufacturing setup. The product was able to integrate with different AOI tool vendor types, which made it a perfect fit for operations. I’m very happy with the implementation."

Jasper Tay, Quality Assurance Manager

Sixsense AI: Upholding Quality and Driving Innovation

"Sixsense deep learning algorithms harness the power of extensive data, empowering us to definitely address quality hurdles with unparalleled precision. Furthermore, Sixsense's solution significantly reduces our response time to quality challenges through its remarkably accurate automated defect classifications. The outcome? A robust competitive advantage and a substantial boost to our bottom line performance."

Mark Tay, Quality Assurance Director

Sixsense in The News

Read on SEMI Newsletter

Read on SEMI Newsletter

Read on PR Newswire

Read on PR Newswire

Read on SGInnovate

Read on SGInnovate

Read on LinkedIn

Read on LinkedIn

Read on Forbes

Read on Forbes

Read on LinkedIn

Read on LinkedIn

Watch on YouTube

Watch on YouTube

Read on Singapore Computer Society

Read on Singapore Computer SocietyBacked By: