Maximize Yield, Productivity and Quality using AI

SixSense’s AI suite turbo-charges fabs and OSAT lines by automating defect review at scale, tracing recurring faults to their root cause, and instantly flagging at-risk wafers. The result: less yield exposure, tighter quality control, higher productivity and higher confidence on every run.

Trusted by Top Semiconductor companies

Unlock 95% of your fab’s hidden intelligence

AI-ADC: End-to-End Visual Inspection, Automated.

AI-ADC is our end-to-end solution for automating visual inspection. With tools for training, deployment, and maintenance, it delivers faster accurate defect classification with fewer labeled samples—reducing cycle time and cleanroom footprint.

- Build AI is end-to-end environment for preparing training data with least effort and building high-accuracy AI models. It enables sampling of most useful images automatically and model training with minimal manual effort and exceptional accuracy.

- ClassifAI runs AI models in production from across AOI tools. It enables high-throughput and low-latency visual inspection with near-zero escapes.

- VerifAI is a smart toolkit to auto monitor and adapt production models — with drift detection and self improvement capabilities to ensure reliable performance in production

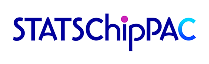

Build AI: Train smarter, not harder

Smart Data preparation

- Pick a diverse, balanced, de-duplicated set—including hard-to-find examples from millions of images.

- AI-assisted label correction at 10x speed.

- Launch once with 0% escapee in production; skip endless retrains and rollbacks.

Classification >> Detection and Anomaly detection

- True classification models—no patched detection or anomaly workarounds.

- Skip bounding boxes; data prep is quick and easy.

- High accuracy even on extremely small and similar looking defects

Large vision foundation models specialized for semiconductors

- Pre-trained on millions of wafer-defect images.

- Thinks like a PhD, not a high-schooler — learns faster, performs smarter.

- Delivers > 95% automation, 0% UR, and up to < 0.05% OR (using image count in just 2-digit instead of 4-digits per class).

Explainable AI

- Verify what your AI learns and launch it only when you believe it!.

- No black-box AI any more!.

- Look inside the model’s brainand see ‘what’ it recognizes as defect.

ClassifAI: Smart & Scalable Defect Classification — Built for High-Throughput Inspection Lines

Seamlessly run in production

- Single model covers hundreds of devices and tools across generations.

- Built-in support for multi-view, multi-tool and multiple magnifications.

- Ready integrations for Rescans, Klarf variants, and incoming defects—deployable by yield engineers.

Operator-First Production Interface

Seamlessly run in production

- AI auto-grades and funnels new defects to the built-in manual review interface - allows for 1-click retraining.

- Familiar Operator UI with minimal learning curve.

- Tools such as interactive wafer maps, hotkeys and color‑coded defect maps give a head start in adoption.

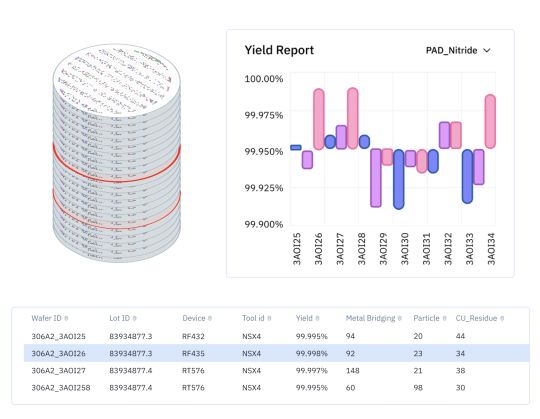

Lot Disposition & Root-Cause Analysis

Built on AI-ADC's trusted labels, Lot Disposition auto-decides pass, hold, rework, or scrap for each lot. It balances yield impact, recurrence patterns, and severity risk, then writes the verdict straight into your systems—eliminating manual sign-offs, avoiding costly excursions, and keeping cycle time lean even at peak throughput.

Dispose AI

Seamless lot disposition

- Surfaces critical repeating defects, wafer-map signatures, and yield outliers.

- Enables auto-lot checkout decisions for yield engineers based on yield criteria and low kill-ratio defects.

- Puts lots with low first pass yield or low final yield on hold for review.

CausifAI

Faster Root Cause Analysis

- Pin points key sources of failure by correlating process tool, lot history and inspection data.

- Quantifies wafer exposure via wafer-stack analytics.

- Reports and charts for yield engineers to trace back sources of true and false yield loss .

Predict AI: Predict and Pinpoint Yield Risks

Predict AI

- Forecast Defects Early – Predict die failure probabilities from inspection, metrology, and process data in early steps.

- Target High-Risk Areas – Identify layers, tools, and patterns driving repeat defects, and dynamically focus sampling where it matters.

- Prevent Scrap Before It Starts – Trigger proactive tool and recipe adjustments and reduce unplanned downtime with self-optimizing, data-driven production.